Introduction

Energy management is a critical goal within the modern maritime industry, aimed at reducing vessel energy consumption amidst rising fuel costs and stringent emission regulations. This involves systematic techniques to analyze energy use, helping operators implement measures to decrease intake in line with sustainability goals. Among various technologies, cold ironing—also known as alternative maritime power—stands out as an effective solution for reducing emissions while ships are docked. This method allows vessels to draw shore-side electrical power, shutting off auxiliary engines that typically generate harmful pollutants. Historical roots trace back to coal-powered ships, where engines would cool while moored, giving rise to the term “cold ironing.” This technology significantly mitigates carbon dioxide and nitrogen oxide emissions, promoting environmental benefits and reducing operational costs. Overall, cold ironing plays a vital role in the movement toward de-carbonizing maritime operations and minimizing the industry’s ecological footprint.

The United States has opted to implement cold ironing at its primary ports as a cost-effective strategy for managing ship emissions. A recent study indicates that the capital required for cold ironing technology at medium-sized ports is approximately $7.4 million, which could lead to annual reductions of 108 tonnes of NOx, 2.7 tonnes of PM, and 4,767 tonnes of CO2, yielding a worth of $1.4 million. In the ideal scenario, the external cost benefits are projected to cover both the initial capital and operating costs within 7.0 years, or 3.5 years with subsidies. Notable U.S. ports employing cold ironing include Long Beach, Seattle, Los Angeles, and Oakland.

The Los Angeles harbor was the first to implement cold ironing technology in June 2004 at the West Basin Container Terminal. California promotes this practice through the “At-Berth Regulation,” which seeks to mitigate emissions from auxiliary engines. The comparison between cold ironing and traditional fuel operations hinges on the relative costs of electricity and on-board fuel, with vessels in California mandated to use marine distillate (LSMGO) in port.

Considering a vessel calling a port in California is charged the commercial rate of US$0.11 per kW-hr, the cost for a 24-hour call drawing 1000kW~1,600 kW will be around half the price of burning LSMGO on board. However, commercial rate of electricity in California is influenced by seasonal demand and could vary from USD 0.11~0.32 per KW-hr but same could be applicable for LSMGO rates as well.

Retrofit of Equipment/ Infrastructure development

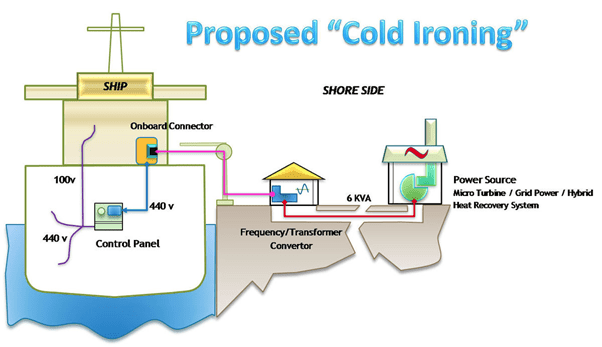

The implementation of cold ironing at ports necessitates specific equipment retrofitting and infrastructure requirements. Ports must ensure the onshore power supply system is adequately equipped, including components such as switch-gear, transformers, and control panels to accommodate vessels drawing external energy.

Additionally, ships must have transformers, power distribution systems, and optional connectors for enhanced flexibility. Ports aiming to facilitate cold ironing should also enhance their electrical capacities and infrastructure for connecting power cables.

Operators engaged in cold ironing must undergo specialized training, which includes arc-flash hazard awareness, technical knowledge of power systems, understanding operational sequences, and communication protocols for safety.

Effective emergency contact strategies should be established alongside a standard safety checklist.

Furthermore, analyzing berth occupancy, vessel traffic, and port efficiency is vital to assess the feasibility and advantages of cold ironing, as improved infrastructure typically correlates with reduced emissions from moored ships.

Charter-parties / Contractual concerns

Charter-parties, which have been established in the marine industry prior to current regulatory challenges, do not standardize the concept of Cold Ironing (CI) or Alternative Maritime Power (AMP). There is ambiguity concerning the responsibilities of owners and charterers regarding compliance with these requirements, particularly in tanker / bulk carrier shipping where such concepts are not traditionally applicable. Charterers currently lack clear guidelines on whether they must arrange or finance shoreside power in compliance scenarios, unlike in liner shipping where obligations are more straightforward.

Conversely, owners are expected to ensure that their vessels comply with local regulations, which may encompass the necessity to equip vessels for shoreside power.

Challenges

Challenges associated with implementing CI/AMP technology include the substantial electrical capacity and infrastructure required at terminals, as well as varying power specifications among different vessel types.

A large vessel might require roughly 1600 kilowatts of electricity when mooring, which can differ considerably. Also, different types of vessels have different voltage and frequency requirement. While most of the vessels operate at 440V power, the large container or cruise ships operate on voltage as high as 6.6 to 11KV.

Furthermore, the effectiveness of CI is sometimes questioned due to potential pollution from coal-powered sources supplying the necessary electricity.

Despite these issues, advancements in CI technology are being driven by evolving policies and legal requirements, and initiatives like those at Long Beach port aim to significantly reduce air pollution in the coming years.

Conclusion

Successful energy conservation hinges not only on economic efficiency but also on environmental awareness, robust business practices, and adherence to regulations.

Efficient ship management focuses on cost-effective fuel use, with “Green Maneuvering” prioritizing eco-friendly navigation to minimize NOx, SOx, and particulate matter emissions.

Effective planning, especially for harbour arrivals and docking, can enhance these benefits despite the challenges posed by “cold ironing,” which is gaining traction despite its associated costs.

Stringent emission regulations and significant penalties for non-compliance are key motivators for this shift, as it offers a feasible solution with tangible benefits.